Blogs

Rock-paper-scissors. Bending Tools and the Rules

By Thijs Hagendijk

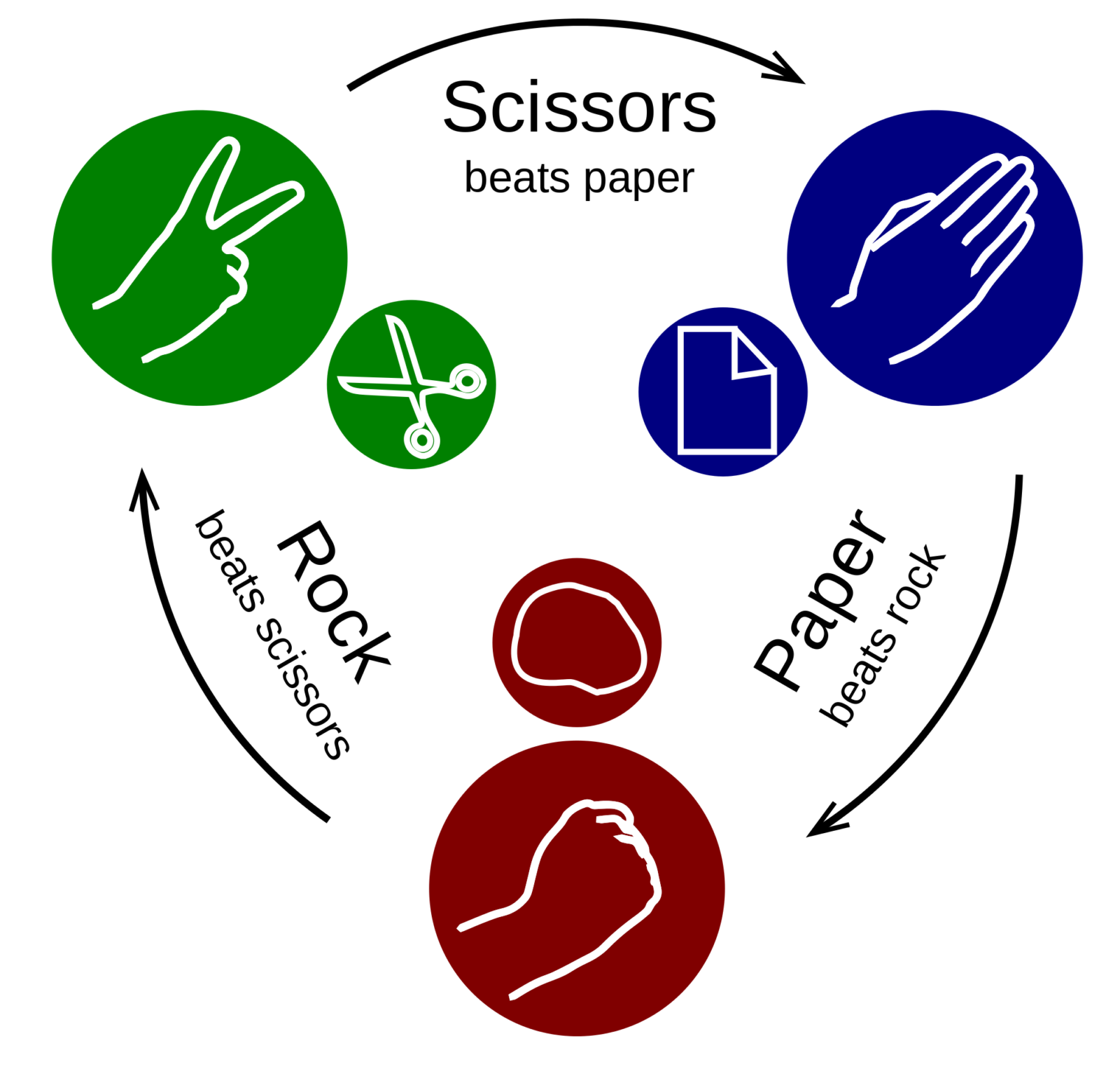

Tools are inert. At least, that is how they appear to us, that is how we buy them, and that is how we need them to be. We use tools to carve, cut and shape materials. We use a hammer to drive nails into walls, a drill bit to make holes in wood and a file to smoothen rough edges. If tools were not inert – when in fact materials could act back on the tools – they would be useless. So each time we pick up a tool, we play a game of rock-paper-scissors. One thing beats the other. The hammer beats the nail like rock beats a pair of scissors. There is no need to question the order of things. The inertness of tools is a given, or is it?

Looking at early modern recipe collections, books of secrets and other artisanal treatises one gets another impression. Rather than being a fixed property of tools, inertness was adjustable and appears to have been a recurring issue for every tool-user. Inertness was not so much taken for granted and knowledge on how to achieve, undo, work around and play with inertness was widely appreciated. Why? Well, knowledge like this enabled people to make, repair and adjust tools. Controlling inertness meant that tools could be turned from something to act with, into something to be acted upon and back again. Additionally, an enhanced understanding of the inertness of tools meant that new sorts of materials could be tackled and processed. For example, art historian Susanne B. Butters extensively demonstrated the relations between Renaissance statues made from porphyry (a purple-red semi-precious stone) and contemporary innovations in the tempering of steel.[1]

Pick up a random collection of early modern recipes and chances are big that you will find instructions on toolmaking and the modification of their inertness. The best example is probably that of iron and steel. Many recipes explained how to get iron and steel from a soft malleable state to a hard inert state, and vice versa. An English translation of the Piemontese’s popular recipe book De’ secreti (1555) already lists about fifteen recipes on this issue that instruct on how “to harden yron”, “to harden a File or other instruments of yron”, “to make any instrument of steele hard and sharpe”, or “to make iron or steele soft.”[2] Not all of these recipes were published. A manuscript of the Antwerp apothecary Peeter van Coudenberghe (c.1580), mostly concerned with pigments, glass and medicine, describes too how “to make steel soft” and presents a recipe for “a powder that makes all metals flow and malleable.”[3]

In his Guidebook for upcoming gold- and silversmiths (1721), the Dutch silversmith Willem van Laer (1674-1722) is very explicit about the merits of knowing how to control the inertness of tools. Even though his main concern is obviously with precious metals, he deems knowledge of iron and steel important too, precisely for this reason. “It often happens that a Gold- or Silversmith needs one or the other instrument which is not always being sold. That is why it is necessary to know the treatment of Iron and Steel.”[4] From Van Laer’s Guidebook, the picture emerges that the production of iron or steel punches, files and chisels was routine business for gold- and silversmiths and this probably held for other crafts as well.

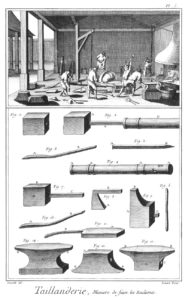

Figure 2: “Taillandier,” Encyclopédie ou Dictionnaire raisonné des sciences, des arts et des métiers, vol. 9 (plates) (Paris, 1771). Plate I: Toolmaker. Method to Make Anvils.

Interestingly, knowledge of inertness and toolmaking did not necessarily mean that early modern people always strove for the most inert and hardest tools. Sometimes they would intentionally use tools that lacked a certain inertness. A beautiful example in this respect was recently found by the Making and Knowing project. The author of a sixteenth-century recipe for a green imitation gemstone in glass, emerald, explicitly writes to use a copper mortar and a copper pestle and counts on the release of small amounts of copper to the mixture to give the glass its colour. The author instructs to pound the ingredients “in a completely copper mortar, & with a pestle of pure copper, and grind them until they become very fine & soft powder; this is a sign that they have taken enough of the substance of copper to give them greenness.”[5]

In brief, the early modern craftsman was very aware of the malleability of tools and their properties. I wonder how good they might have been at a simple game of rock-paper-scissors. Rock beats scissors? Not necessarily so!

[1] Suzanne B. Butters, The Triumph of Vulcan. Sculptors’ Tools, Porphyry, and the Prince in Ducal Florence (Florence: Leo S. Olschki, 1996).

[2] The Secrets of the reuerend Maister Alexis of Piemont etc. Translated by William Ward (London, 1595), pp. 242-244.

[3] E. Vandamme, “Een 16e-eeuws Zuidnederlands receptenboek,” Jaarboek van het Koninklijk Museum voor Schone Kunsten (1974), pp. 101-137.

[4] Willem van Laer, Weg-wyzer voor aankoomende Goud en Zilversmeeden (Amsterdam: 1721), p. 197.

[5] “Minimal edition of BnF Ms Fr 640,” fol. 100v. Making and Knowing project, accessed 30 October 2017. Furthermore: Kathryn Kremnitzer and Siddharta V. Shah, “Making Emerald. Imitation as Working Method,” paper presented at the SHAC Postgraduate Workshop on Colouring & Making in Alchemy and Chemistry, Utrecht University, 26 October 2016.